Transmission Ratio Calculation In Ball Mill

.jpg)

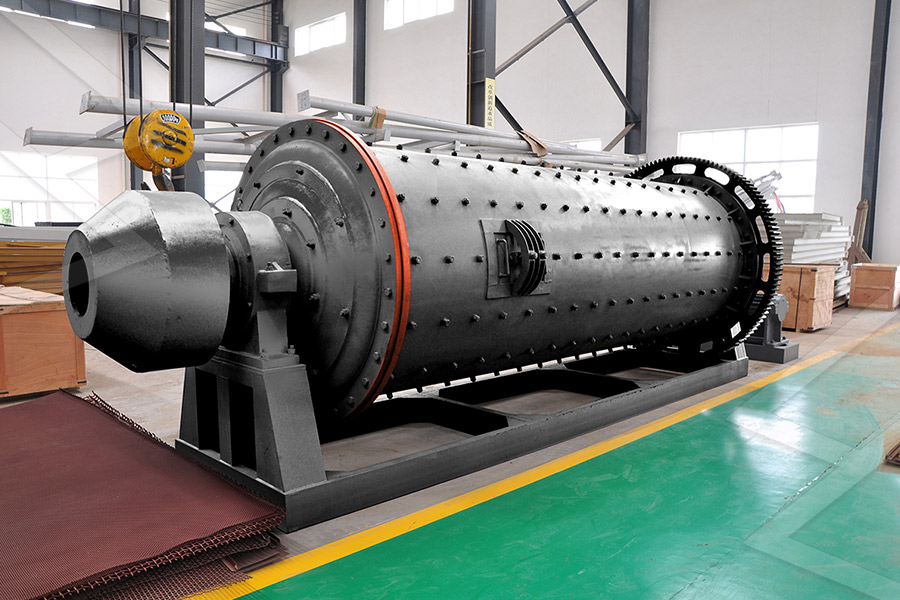

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 The torque required to rotate the ball mill of material weight 1,99,028 N is to be calculated from the centre of the mill to the periphery of the mill In the given data the ball mill 2024年8月15日 To aid in this, we offer a free online calculator to compute and report all necessary parameters The rising prospects of mechanochemically assisted syntheses hold Navigating Ball Mill Specifications for Theory‐to‐Practice 2015年6月19日 Ball Mill Power Calculation Example #1 A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) The required product Ball Mill Design/Power Calculation2020年12月26日 The main purpose of this study is to determine the proper design of power transmission system for rotational ball mill Power transmission is the part of a mechanical Design and Selection of A Transmission System for Installation of 2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide BALL MILLS Ball mill optimisation Holzinger ConsultingWhat is the circulating load ratio in your ball milling circuit? There is a rapid and easy way to calculate it from any set of circuit size distribution data for the standard circuit arrangement shown in Figure 1, as followsGrinding Bulletin #1 – Metcom Technologies

.jpg)

Design and Performance of Ball Milling for Powder

2022年3月8日 Therefore, the present work concentrates on mixing of two available powders with a proper proportion in a ball mill by fabricating it, compacting the powder mixture in hydraulic 2023年11月2日 The software uses the particular power model (Bond/Barratt, Morrell Mi, etc) to determine what is the transfer size where the ratio of E SAG to E ball matches the ratio of mill Modelling: Transfer size limits According to Formula 1, the transmission ratio of the ball mill is 0282 At this time, V b depends on the size of the ball mill r b and the speed of the ball mill n The minimum ball mill used in Energybased ball milling process design and dispersion 2003年5月7日 The critical speed of the mill, c, is defined as the speed at which a single ball will just remain against the wall for a full cycle At the top of the cycle =0 andTECHNICAL NOTES 8 GRINDING R P King Mineral Tech2020年5月1日 The main aim of this study is to improve the processing capacity of the largescale ball mill Taking a Φ549 × 883 m ball mill as the research object, the reason for the low Enhancing the capacity of largescale ball mill through CALCULATED VALUE OF DF, % Maximum ball size (MBS) Please Enter / Stepto Input Values Mill Feed Material Size F, mmball mill calculations, grinding media filling degree, ball size, mill

.jpg)

Optimization of mill performance by using online ball and

2010年4月23日 Optimization of mill performance by using online ball and pulp measurements2021年3月12日 Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the BALL MILLS Ball mill optimisation Holzinger Consulting2018年4月17日 Obviously, the SAG mill is consuming more and the ball mill less power than was predicted by the empirical method, but the overall total is 995% of the predicted total Autogenous and SAG SemiAutogenous Mill Design CalculationsA general rule of thumb from the CRC handbook on mechanical alloying and milling denotes a 10:1 ratio for small capacity mills (SPEX), but large capacity mills (attritor) can have BPR of Best way to determine the balltopowder ratio in ballmilling?working parameters of highspeed vibrating ball mills The parameters are generally designed based on the theoretical calculation of tumbling ball mills and are optimized based on transmission ratio calculation in ball millThe first step is to recognize the relationship between the ball mill circuit circulating load ratio (CLR) and the overall circuit capacity or efficiency (See Bulletin No 1 on how to calculate Grinding Bulletin #4 – Metcom Technologies

.jpg)

Effect of circulating load and classification efficiency on

2014年10月20日 Ball mill and high pressure water jet were used respectively to conduct grinding experiments on Bayan Obo ore according to its complex association and 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their (PDF) Grinding Media in Ball MillsA Review ResearchGate2023年2月11日 residence time ball mill model to constrain simulations and prevent Zoverfilling [ and a loss of grinding The database provided by Shi on residence time, and his calculation Digital Solutions to Evaluate Ball Mill Circuit 2021年1月1日 The signal was first detrended by a complete ensemble empirical mode decomposition and then reconstructed using a correlation coefficient method The filling ratio, An improved method for grinding mill filling measurement and 2024年2月28日 Dive into the specifics to elevate your ball mill efficiency 1 Mill Volume Analysis The volume of your ball mill sets the stage for efficient milling Calculate it by multiplying the total mill volume, accounting for void spaces, by Calculate Formula for The Balls Needed in a Ball 2021年11月1日 The filling ratio, ratio of particle to ball and mineral weight were varied to control the mill load The initial ratio of grading ball was 30 mm: 40 mm: 50 mm: 70 mm = 30: 20: 30: Assessing load in ball mill using instrumented grinding media

Circulating Load Calculation Formula 911Metallurgist

2015年2月21日 For example your ball mill is in closed circuit with a set of cyclones The grinding mill receives crushed ore feed The pulp densities around your cyclone are sampled and 2014年3月1日 An industrial ball mill operating in closed–circuit with hydrocyclones was studied by five sampling surveys The aim of the present study was to optimise operating parameters (PDF) Circulating load calculation in grinding circuits2019年2月1日 The ignition time (t ig) of the mechanically induced selfsustaining reaction (MSR) process involving the formation of TiB 2 from Ti/2B elemental mixtures was used to study the Effects of the speed ratio on the efficiency of planetary mills2020年12月26日 In this study, belt and pulley system was selected as power transmission type The calculation had been carried out to obtain the suitable power transmitted by belt based on Design and Selection of A Transmission System for Installation of 2022年1月19日 Ball mill Most ball mills, even in primary applications, have a finer ore feed size; this requires some impact but not enough to increase the media consumption or even break EBOOK Three factors that determine the wear life and2024年8月15日 Planetary ball mill specific parameters that directly influence the energetics a, Illustration of a mill and the relevant parameters that contribute to the effective impact velocity Navigating Ball Mill Specifications for Theory‐to‐Practice

(PDF) Effects of Ball Size Distribution and Mill Speed and

2020年7月2日 In recent research done by AmanNejad and Barani [93] using DEM to investigate the effect of ball size distribution on ball milling, charging the mill speed with 40% small balls 2025年5月6日 Transmission Reduction 30: 1 Ratio Speed Reducer Gearbox for Lifter Mining Ball Mill, Find Details and Price about Gear Box Reducer from Transmission Reduction 30: 1 Transmission Reduction 30: 1 Ratio Speed Reducer Gearbox 2015年10月15日 A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a Calculate Ball Mill Grinding Capacity 911Metallurgist2021年11月10日 Now by using the gear ratio formula we looked at earlier, we can determine the ratio across the gears The first gear set is 30 over 10 or 3 to 1 And that the ratio across the What is Gear ratio? [How to calculate Gear Ratio with Formula]2021年2月4日 IV BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades A ATTRITORS AND BALL MILLS HOW THEY WORK Union 2021年1月1日 Comchambered with the design of Φ 35 × 13m threechamber ball mill, the design process of ball mill is described in detail General arrangement of the mill Filling rate of (PDF) Design of Threechamber Ball Mill ResearchGate

Global optimization of reliability design for large ball mill

2013年11月1日 Gear transmission is one of the most important components of the large ball mill, directly affecting the reliability of the entire ball mill, and the breaking and wear (shown in Fig 2019年12月19日 Space balls are used in high speed or high precision ball screws to reduce the balls rubbing against each other, typically under low load and 1um order resolution actuation 1) Rack and pinion Seoul National University2020年5月1日 The main aim of this study is to improve the processing capacity of the largescale ball mill Taking a Φ549 × 883 m ball mill as the research object, the reason for the low Enhancing the capacity of largescale ball mill through CALCULATED VALUE OF DF, % Maximum ball size (MBS) Please Enter / Stepto Input Values Mill Feed Material Size F, mmball mill calculations, grinding media filling degree, ball size, mill 2010年4月23日 Optimization of mill performance by using online ball and pulp measurementsOptimization of mill performance by using online ball and 2021年3月12日 Ball mills and grinding tools Cement ball mills are typically twochamber mills (Figure 2), where the first chamber has larger media with lifting liners installed, providing the BALL MILLS Ball mill optimisation Holzinger Consulting

Autogenous and SAG SemiAutogenous Mill Design Calculations

2018年4月17日 Obviously, the SAG mill is consuming more and the ball mill less power than was predicted by the empirical method, but the overall total is 995% of the predicted total A general rule of thumb from the CRC handbook on mechanical alloying and milling denotes a 10:1 ratio for small capacity mills (SPEX), but large capacity mills (attritor) can have BPR of Best way to determine the balltopowder ratio in ballmilling?working parameters of highspeed vibrating ball mills The parameters are generally designed based on the theoretical calculation of tumbling ball mills and are optimized based on transmission ratio calculation in ball millThe first step is to recognize the relationship between the ball mill circuit circulating load ratio (CLR) and the overall circuit capacity or efficiency (See Bulletin No 1 on how to calculate Grinding Bulletin #4 – Metcom Technologies2014年10月20日 Ball mill and high pressure water jet were used respectively to conduct grinding experiments on Bayan Obo ore according to its complex association and Effect of circulating load and classification efficiency on 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their (PDF) Grinding Media in Ball MillsA Review ResearchGate